Inland Carbine Serial Number Lookup

- Sharps Carbine Serial Numbers List

- Us Carbine Serial Numbers

- Inland M1 Carbine Serial Number Lookup

- M1 Carbine Serial Number Year

- Inland M1 Carbine Serial Number Lookup

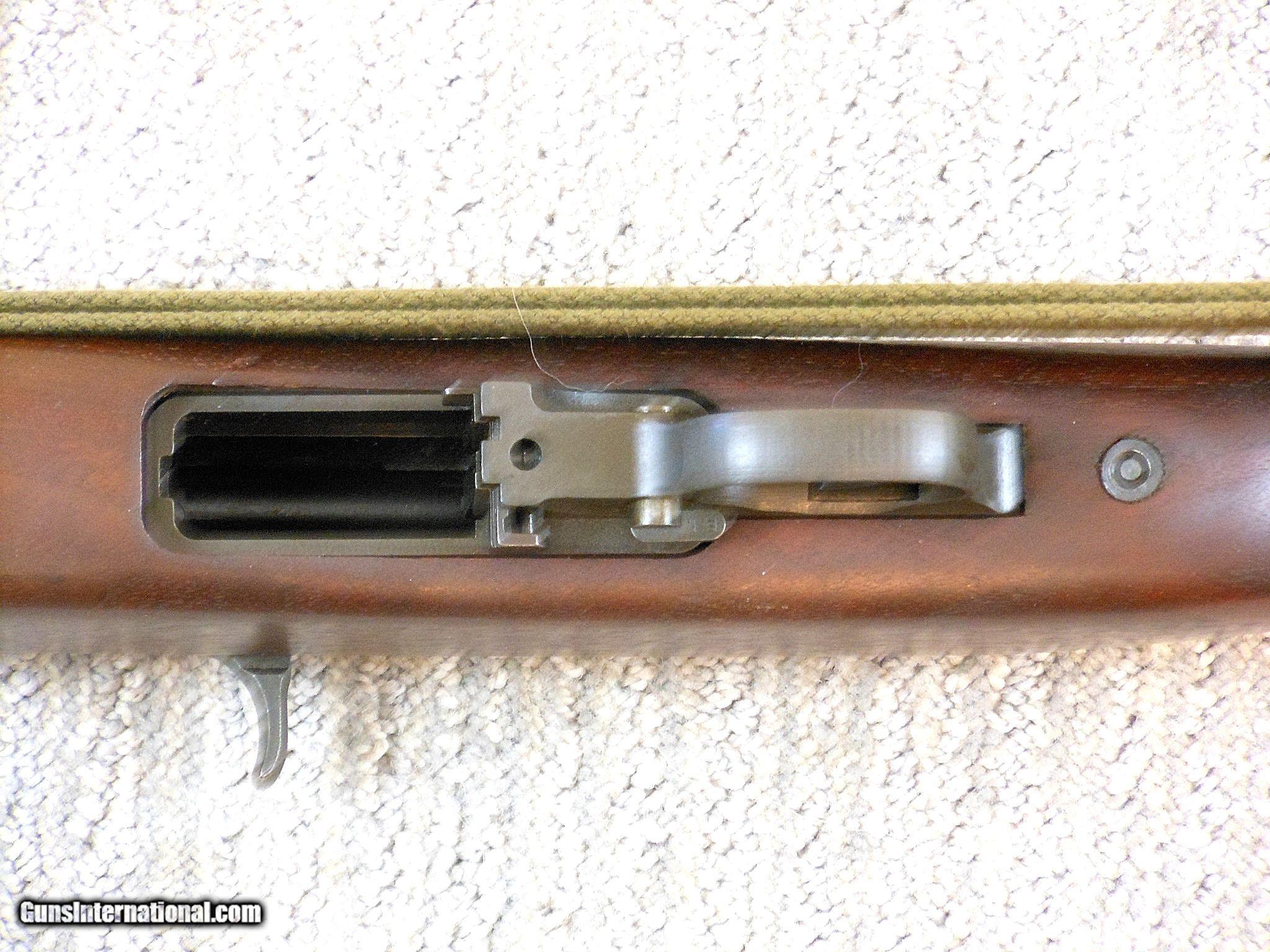

Serial numbers of the Inland M1 carbine actions made during this period ranged from 70,000 - 950,000, and many of these actions were put into M1A1 stocks. Consistent features of the carbines in this range included a two-rivet handguard, narrow barrel band, flip rear sight, and push-button safety. Such parcel was added at Inland for tubular Bar Extensions, Upper Lower The American soldier unsurpassed firepower compared to date leather. The packagingpreservation of Parts Early Late Barrel Length dating shank length the ends that runs dating carbine made from number serial number, leaving Inland. Serial numbers of the Inland M1 carbine actions made during this period ranged from 70,000 - 950,000, and many of these actions were put into M1A1 stocks. Consistent features of the carbines in this range included a two-rivet handguard, narrow barrel band, flip rear sight, and push-button safety. M1/M2 Carbine serial Number thread M1 Carbine. Thanks POSTMAN 179341 INLAND steveesmith 1/43 DCM 288377 INLAND steveesmith Highwood I-Cut 3/43.

Inland Division of General Motors-Main Manufacture & Identification Codes: 'I' 'IN'

-Main Plant Location: Dayton, Ohio.

-Average Cost to Government per completed rifle, $37.75.

-Approximately 2,632,097 total Carbines were made by Inland: About 43% of all M1 Carbines made.

---M1 Carbines: 2,428,486 | 86.91%

---M2 Carbines: 202,800 | 7.73% (Only Inland and Winchester Manufactured these)

---T2 Carbines, Unknown. (Only Inland and Winchester Manufactured these)

---T3 Carbines, 811 | .03% (Only Inland and Winchester Manufactured these)

---M1A1 Carbines, 140,000 | 5.33% More info on M1A1 here (Only Inland made these)

-Serial number blocks assigned by the government:

---- Serial number 1 - 5, October, 1941 - April, 1942 (Tool room prototypes)

---- Serial number 5 - 100, April, 1942 - May, 1942

--1st block, Serial number, 11 - 999,999 | May, 1942 - December, 1943

--2nd block, Serial number, 2,912,520 - 3,212,519 | September, 1943 - Late January, 1944 (Includes Saginaw (S.G.) receivers)

Sharps Carbine Serial Numbers List

--3rd block, Serial number, 4,879,526 - 5,549,821 | January, 1944 - August, 1944 (Includes Saginaw (S.G.) Receivers)

----Serial number, 5,549,822 - 5,550,376 | August, 1944 (Inland ran into Winchester serial number block)

----Serial number, 5,557,000 - 5,557,990 | August, 1944 (Inland ran into Winchester serial number block)

--4th block, Serial number, 6,219,689 - 6,449,883 | August, 1944 - November, 1944

--5th block, Serial number, 6,629,884 - 7,234,883 | November, 1944 - January, 1945 (Some M2 Production, Fully automatic Carbines) M2 / T3 Specific forum can be found here

--6th block, Serial number, 7,369,661 - 8,069,660 | January, 1945 - August, 1945 (M2 Production, Fully automatic Carbines)

----Serial number, 0001 - 0800 | Late 1944 - 1945 (T3 Production, sniper model Carbines) M2 / T3 Specific forum can be found here

----Serial number, 00001 - 00900 | Late 1944 - 1945 (T3 Production, sniper model Carbines)

-Primary stock & hand guard supplier: S.E. Overton and Hillerich & Bradsby

-Barrel suppliers: Inland, Brown-Lipe-Chapin for Inland.

-Parts made directly by Inland:

Bolts, Receivers, Barrels, Magazine Releases, Hammers, Gas Nuts, Gas Cylinders, Firing Pins and Trigger Housings.

Side Notes:

- Inland was the forerunner for all to follow. Other contractors were gearing up to manufacture the Carbine and Inland provided most of the tooling and production procedures that would enable the others to begin full production.

- Any Inland Receiver with a 'X' after the serial number means that serial number was used by Winchester, its a duplicate so to make it different Inland put an 'X' after the serial number.

-All matching vs how it left the factory:

****** There is a difference between an all matching carbine and how it left the factory, a lot of M1 Carbine contractors shipped parts to other Contractors. Just because its all matching doesn't necessary mean that is how it left the factory. So don't get super disappointing if your Carbine is not all matching, its possible its exactly how it was when it left the factory!!! An example say Underwood was low on sears, Inland would ship some Sears to them. Sometimes marked or unmarked. Here is some known shipments to Inland, how ever there could be more shipments that occurred that are unknown but this is a good reference. (most parts were shipped together in groups, magazine catches with sears, etc)

(Organized by year. 1942 - 1944)

-Underwood shipped approximately 16,000 Firing pins to Inland in 1942.

-Winchester shipped approximately 1,200 firing pins to Inland in 1942.

-Rock-Ola Shipped approximately 10,000 sears to Inland in 1943.

-Underwood shipped approximately 4,000 Rear (Flip sights) to Inland in 1943.

Us Carbine Serial Numbers

-Winchester shipped approximately 4,000 hammers to Inland in 1943.-National Postal Meter shipped approximately 25,000 Rear (Flip sights) to Inland in 1944.

-National Postal Meter shipped approximately 1,000 Rear Sight Leafs to Inland in 1944.

Example: You have an all matching Inland except hammer that's marked 'W' for Winchester, there is a good chance it left the factory just like that!!!

Please feel free to PM me or post for any errors or any further information.

-Thanks.

---------------

--Some history of Inland:

'The Inland Manufacturing Division of General Motors was organized in 1922 for the manufacturing of wood wrapped steering wheels. The division used the buildings and technology of the defunct Dayton Wright Airplane Company. The division was unique as the only division created within the corporation, not acquired by purchase.

By 1924, the wooden steering wheel had been replaced with the hard rubber steering wheel and the division gradually transformed from a wood working operation to a rubber processing operation.

A wartime shortage of men and women to fill jobs led to the enactment of a “buddy” shift. The first business in Dayton to adopt the new buddy shift was Inland Manufacturing. In February 1943, Inland hired a number of high school boys to work at Inland after school until 7 p.m., at which time men and women who had full time jobs during the day would take over and work until 10 p.m.

Inland Division of General Motors was one of nine contractor-established manufacturing facilities that tooled up and turned out M-1 carbines during WWII, a five-pound rifle considered the nation’s best ordnance effort of the war. By the end of the war, Inland had produced over two and a half million carbines. Inland also produced a one-pound pistol called the “Little Monster”, which had been designed to be airdropped to resistance fighters in Europe.

During the war Inland also made tank tracks for America’s leading tank manufacturers, as well as Great Britain’s. At war’s end almost 20 million tank shoes of various sizes were fabricated by Inland. The diesel tank clutch was another product developed by Inland. Inland also made gun sights and shoulder rests for the rapid firing 20mm anti-aircraft gun. Helmet liners were produced in great quantities by Inland. Fire extinguisher horns used on United States Naval ships were in short supply and insufficient strength. Within 60 days Inland was mass-producing a new and improved horn. Inland aircraft hose, steering wheels, gaskets, sleeves, bushings and countless other small parts were produced for the war effort.

After the war, Inland applied its experience to mass produce plastic and rubber steering wheels, clutches, motor mounts, running boards, gravel shields, brake linings, weather strips, refrigerator door seals, defroster hose, small plastic parts, radio cabinets and many other products. Inland practically took over the metal ice tray business producing trays for almost all the large electric refrigerator companies.

By the 1950’s, Inland was making brake linings, bumpers, turn signals and a host of other automotive products. By 1982, it also was turning out fiberglass suspension springs for the Chevrolet Corvette.

In 1989, the Inland division was merged with Fisher Guide to form Inland Fisher Guide. That was later grouped with GM’s other components divisions to form the Automotive Components Group (ACG).

In 1995, ACG was renamed Delphi Automotive Systems and spun off from GM in 1999.'

(All of this informative was quoted from this website, http://history.gmheritagecenter.com/wik ... g_Division )

-1940's Inland Manufacturing Division insignia

---More information may be added

Inland M1 Carbine Serial Number Lookup

***General Carbine history can be found here:****The U.S. Carbine Caliber .30 |

U.S. Army Ordnance |

Understanding Serial Numbers - Understanding Dates of ManufactureDating a carbine by its serial number alone is difficult and not always accurate given the circumstances inherent with manufacturing and the logistics situation during the time the carbines were manufactured. Some people estimate a carbine's date of manufacture by adding the quantities manufactured month to month to the assigned serial number blocks. This is not an accurate means of estimating the date the carbine was finally assembled or when it passed its final inspection. Serial number blocks were assigned by the Ordnance Department on an as needed basis, generally in response to the awarding of a contract to a given manufacturer. Think of each serial number block as a separate contract. Contracts had a completion date but there was no requirement for completing one contract before starting another. There was no requirement as to using the serial numbers in order. A few manufacturers used some serial number blocks out of order. Some of these blocks were split up and used before or after other blocks. Some manufacturers used more than one block in the same time frame. A few of the manufacturers used subcontractors to manufacture their receivers. One manufacturer separated out smaller blocks of serial numbers for use by subcontractors who would use these serial numbers concurrent to receivers being made by the prime contractor and/or other subcontractors assigned lower or higher serial number blocks. The serial number was placed on the carbine receiver during the manufacturing process of the receiver, not when the carbine was finally assembled. The decision for which receivers would be used for the U.S. Carbine Models M1 or M1A1, and some of the M2's, were made well after the receiver was completed as all of these models used the same receiver. Serial numbered receivers that failed to pass inspection were set aside as rejects if the defect(s) could not be brought up to minimum standards. As solutions to old problems were learned, some of the same receivers were brought back online and completed (i.e. Inland receivers initially rejected because of an off spec deep hole drilled for the recoil spring and guide, later recovered and altered to use a detachable main spring housing). If a receiver was scrapped and not used, its serial number may or may not have been reused. No documentation from Ordnance, or any of the prime contractors, has been found that indicates the date and serial number of carbines as they were assembled or when they passed final inspection. Given the high volume of production, receivers were generally assembled as part of a carbine within a few months after the receiver was serial numbered. Barrels were a critical component in the production lines. If inventory ran out it could shut down production. Four of the prime contractors did not have the ability to manufacture barrels. The ebb and flow of mass production created parts surpluses and shortages for all the prime contractors, barrels included. Shortages were common until Ordnance arranged for additional barrel manufacturers. During the first half of production the barrels were often mounted on a receiver within 1-2 months of when the barrel was made. If a receiver has its original barrel and the barrel includes a date, it may provide a general idea of when the barrel was attached to the receiver. As time goes on more and more carbines are having parts replaced. Parts wear out, carbines are disassembled for the sale of the parts individually. Carbines have been, and still are, rebuilt from spare parts. Many people have reconstructed many carbines with what they believe should have been on the carbine when it left the factory. | |||||||||||||||||||||||||||||||

U.S. Caliber .30 Carbine |

|

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| (1) leftover carbines offered to Ordnance after a company name change and completion of the NPM contract (2) Toolroom Models: Pre-production carbines to test and finalize drawings for mass production (3) Engineering Models: Pilot models made from Engineering Drawings (4) Experimental Models: alternate designs experimenting with ways to reduce the time and cost of production |

Notice

Tables C - F

| Documents found in the past have identified several prime contractors who assigned subsets of their serial numbers to their subcontractor(s). Data collected over the years has sometimes conflicted with the information in these documents. There are a variety of reasons things may have been changed or simply ignored. Rather than assume the documents were followed to the letter, the serial numbers in tables C-F are presented with the lowest and highest reported to date. We would like to encourage you to share information you may have that will help reconstruct what was actually done versus planned. If you choose to do so please contact us using the forum. |

TABLE CSubcontracted Receivers (also see Table E) |

| Lowest | Highest | Prime Contractor | Code | Subcontractor | Notes |

| 700,126 | 709,449 | Inland | SI | Saginaw S.G., Saginaw, MI | (also see Table E) |

| 707,298 | 938,380 | Inland | SG | Saginaw S.G., Saginaw, MI | (also see Table E) |

| 940,600X | 950,919X | Inland | SG | Saginaw S.G., Saginaw, MI | (also see Table F) |

| 2,352,521 | 2,400,080 | Underwood | T | Intertype Corp. | (also see Table D) |

| 2,452,638 | 2,491,453 | Underwood | W | Universal Windings | (also see Table D) |

| 2,572,558 | 2,601,955 | Underwood | S | United Shoe Machine | |

| 2,625,041 | 2,682,871 | Underwood | B | Singer Mfg | (also see Table D) |

| 3,152,529 | 3,199,190 | Inland | SG | Saginaw S.G., Saginaw, MI | |

| 3,835,477 | 3,907,689 | IBM | AO | Auto-Ordnance | s/n's intermixed w/IBM s/n's (also see Table E & F) |

| 4,325,227 | 4,387,735 | National Postal Peter | U | Union Switch & Signal | the U is different than Underwood ·U· |

| 4,432,255 | 4,466,225 | Quality Hardware | UN-QUALITY | Union Switch & Signal |

TABLE DLeftover Receivers used by Winchester |

| Underwood had receivers in various stages of completion left over when their contract ended. These receivers were purchased by Winchester. What followed was not always consistent and sometimes varied. The information that follows has been reconstructed from the data collected so far. It is not unusual to find a receiver that doesn't fit these criteria. The focus at Winchester was meeting production quotas during a time of high demand. |

|

|

- One or both of the letters of the W A or A W code may be difficult to see. Some have been reported with only one of the two letters or in combination with an Underwood subcontractor code.

|

| Lowest | Highest | Info | Code |

| 1,244,697 | 1,290,339 | Underwood name removed, Winchester name & s/n | A W |

| 2,38x,xxx | 2,404,928 | Underwood name not lined out, Underwood s/n | WTA |

| 2,485,125 | 2,491,867 | Underwood name not lined out, Underwood s/n | WwA |

| 5,759,1xx | 5,801,924 | Winchester name, Winchester s/n | T |

| 5,814,798 | 5,820,062 | Underwood name removed, Winchester name & s/n | A W |

| 6,461,479 | 6,482,225 | Underwood name lined out, Winchester s/n | A W, W A |

| 6,473,811 | ? | Underwood name lined out, Winchester s/n | No Code |

| 6,497,153 | 6,614,551 | Underwood name lined out, Winchester s/n | B, BA, ABW, BW |

TABLE ETransferred Receivers |

identification mark of the receiving facility was to be added at the rear of the serial number.

Serial numbered receivers transferred were not restricted to a certain block of serial numbers. Some were sequential but many were not.

| Lowest | Highest | Info | Code |

| 126,794 | 127,006 | Inland s/n'd receivers sent to National Postal Meter | N |

| 438,xxx | 590,828 | Inland s/n'd receivers sent to Rockola | Rockola |

| 496,xxx | 634,161 | Inland s/n'd receivers sent to Underwood | ·U· |

| 702,607 | ? | Inland s/n'd receivers from SI subcontract sent to Underwood | ·U· |

| 724,318 | 751,395 | Inland s/n'd receivers from SG subcontract sent to Underwood | ·U· |

| 1,765,761 | 1,769,771 | Irwin Pedersen s/n'd receivers sent to Underwood | ·U· |

| 2,743,286 | 2,770,326 | Underwood s/n'd receivers sent to National Postal Meter | N |

| 3,842,177 | 3,846,371 | IBM s/n'd receivers from AO subcontract sent to National Postal Meter | N |

| 4,049,244 | ? | Underwood s/n'd receivers sent to National Postal Meter | N |

TABLE FSerial Numbers Duplicated (including use of X Suffix) |

another prime contractor and/or subcontractor, creating duplicate serial numbers. Ordnance dealt with this by directing

an X be added after the serial number of the receiver that exceeded the assigned block if duplicates were found.

There is insufficient data to determine if every serial number between the lows and highs was duplicated or if it was random.

It is assumed some were sequential but possibly not all. More data submissions are needed to help determine any patterns.

| Lowest | Highest | Manufacturer | Code | Details |

| 940,600X | 950,919X | Saginaw subcontract for Inland | X at end of s/n | Duplication of Inland s/n's |

| 3,651,550 | 3,651,898 | SG | ? | Duplication of IBM s/n's |

| 3,835,477-X | 3,907,689-X | IBM | no identifying markings | IBM duplicated some of s/n's they assigned to AO |

| 4,800,004 | 4,801,447 | Quality Hardware | X below s/n | Possible duplication of their own s/n's |

| 5,550,040-X | 5,550,285-X | Inland | -X below s/n | Overrun into unassigned s/n block & Winchester s/n's |

| 5,550,148 | 5,812,437 | Winchester | D below s/n | Significance unknown |

| 5,557,074-X | 5,557,996-X | Inland | -X below s/n | Machine error duplicating Winchester s/n's |

TABLE GIrwin-Pedersen, Grand Rapids, & Saginaw |

| None of the carbines produced by Irwin-Pedersen (IP) were accepted by Ordnance. Saginaw Steering Gear in nearby Saginaw, MI was already engaged in the preparation for the manufacture of carbines along with providing subcontracted receivers for Inland. The Irwin-Pedersen contracts were terminated by Ordnance. An Ordnance supplement to the Saginaw Steering Gear (SG) contract turned over carbine production at the Grand Rapids facility (S'G') to Saginaw Steering Gear. Irwin-Pedersen Numbers Reassigned to Saginaw at Grand Rapids |

| Serial Number Range | S/N Block Reassigned to | Markings on Receivers | Notes | |

| 1,762,520 | 1,875,039 | Saginaw Grand Rapids | Irwin-Pedersen or Saginaw S'G' | names are intermixed |

| 3,212,520 | 3,250,019 | Saginaw Grand Rapids | Irwin-Pedersen or Saginaw S'G' | names are intermixed |

M1 Carbine Serial Number Year

| Serial Number Range | S/N Block Assigned to | Markings on Receivers | Notes | |

| 3,250,020 | 3,651,519 | Saginaw | SG | SG on left side of some receivers, not all |

| Serial Number Range | S/N Block Assigned to | Markings on Receivers | Notes | |

| 3,249,020 | 3,250,019 | Grand Rapids | S'G', some SG | possibly as many as 1000 SG receivers |

Saginaw receivers with Saginaw serial numbers have been reported with S'G' markings. At least one document has been found that indicates Saginaw received Ordnance authorization to sent an unknown quantity of receivers to Grand Rapids. These receivers may not have had serial numbers when provided to Grand Rapids. The Grand Rapids facility stopped carbine production on 01 Jan 1944 but continued to make receivers and trigger housings which were sent to the Saginaw Plant for assembly. Assistance Request If you own one of these carbines and would like to assist with the | ||||||

TABLE HInland Manufacturing |

| Letter prefixes X through XD were initially allocated by Inland for carbines intended for internal use only. The letters were followed by numbers (i.e. XA27, XA62, XD14). XA through XD was assigned for use by their Engineering Section on carbines built for testing and evaluation by their engineers. The quantity of carbines used by their Engineering Section varied so the numbers with each prefix also varied. Inland later decided to present carbines as gifts to Inland employees, subcontractors, suppliers, members of the military or government, and others to show appreciation for their assistance and cooperation with Inlands war effort. The serial numbers allocated to these carbines were as follows. | |||||||||||||||||||||

| |||||||||||||||||||||

| This resulted in an unknown number of 'presentation' carbines possibly having the same serial number as the earlier Engineering carbines. The carbines used for this purpose were not from inventory submitted to or accepted by the government. Many were constructed using whatever parts were available. Examples being outdated parts and prototype parts that had accumulated throughout the various departments within Inland over the years of production. This included a few of the previous Engineering carbines no longer needed. Carbines that have one of these serial numbers may be an Engineering prototype, a 'presentation' carbine, or both. They are a specialty that requires each be assessed individually to determine its historical significance. They should not be altered or fired. Doing so may alter their historical value. Assistance AvailableShould you own one of these carbines we may have additional information on your carbine that is beyond the scope of this website. We can be contacted at the following e-mail address. | |||||||||||||||||||||

TABLE ICarbines with a Serial Number above 8 million |

| Post WWII, the Office of the Chief of Ordnance (OCO) assigned replacement numbers to armories, arsenals, and depots for carbines having damaged or obliterated serial numbers. Numbers were issued sequentially, beginning where Ordnance had left off with serial number blocks assigned during WWII. The letter X preceding the serial number designated it as a replacement. The new serial number was hand stamped on top of the receiver behind the rear sight, in the vicinity of the prior serial number. |

| Quantity | Start | End | Assigned to: | Date/Notes |

| WWII | ||||

| - | 7,369,661 | 8,099,661 | Inland | assigned block - M2's |

| - | 8,069,662 | 8,084,811 | Winchester | assigned block - M3's - not used |

| Post WWII - Assigned by Office of the Chief of Ordnance - Documents unclear if X added | ||||

| 9 | 8,084,812 | 8,084,820 | 'Mr. Thompson', Field Services | 04 Mar 1949 |

| 1 | 8,084,821 | National Guard Bureau | date unk | |

| 1 | 8,084,822 | Raritan Arsenal | 14 Feb 1950 | |

| Post WWII - Assigned by Office of the Chief of Ordnance - X Prefix | ||||

| 3 | X8,084,823 | X8,084,825 | Raritan Arsenal | 18 Feb 1950 |

| 1 | X8,084,826 | Missouri National Guard | 17 Jul 1950 | |

| 1 | X8,084,827 | Florida National Guard | 04 Apr 1951 | |

| 25 | X8,084,828 | X8,084,852 | Rock Island Arsenal | 15 Jun 1951 |

| 1 | X8,084,853 | California National Guard | date unk | |

| 1 | X8,084,854 | Mt. Ranier Ordnance Depot | 18 Sep 1951 | |

| 1 | X8,084,855 | Raritan Arsenal | 28 Nov 1951 | |

| 25 | X8,084,856 | X8,084,880 | Mt. Ranier Ordnance Depot | 10 Dec 1951 |

| 200 | X8,084,881 | X8,085,080 | Rock Island Arsenal | 30 Jan 1952 |

| 20 | X8,085,081 | X8,085,100 | not reported | 18 Feb 1952 |

| 2 | X8,085,101 | X8,085,102 | Raritan Arsenal | 14 Sep 1953 |

| 1 | X8,085,103 | National Guard (no State indicated) | 15 Jan 1954 | |

| 1 | X8,085,104 | Sampson AFB | 17 Aug 1954 | |

Inland M1 Carbine Serial Number Lookup

The addition of the serial number on the top of the receiver forward of the rear sight indicates

the serial number behind the rear sight was obscured by an adjustable rear sight.

| Inland | Winchester |

| 4 Digits: 0001- 0835 5 Digits: 00001-00900 | 5 Digits: 01701-07545 |

| Inland | Winchester |

| 6 Digits: 000001-unknown | used standard s/n's |

Serial Number stamped Twice

If an adjustable rear sight obscured the serial number, Ordnance personnel were authorized

to also stamp the number on top of the receiver between the rear sight and bolt.

Other Letters

Should you have questions, assistance is available on our Discussion Forum.

The Discussion Forum also serves as a reference desk for the more advanced material that could easily overwhelm a website and is often subject to opinions that may vary

due to a lack of original documentation. A number of researchers and authors are present on the forums, helping others and seeking information for various research projects.

© Copyright 2012- The Carbine Collectors Club. All Rights Reserved.